Plant extract (Plant extract) is a plant as raw material, according to the use of the extracted end product needs through the physical and chemical extraction and separation process, directed to obtain and concentrate one or more of the active ingredients in the plant, without changing the structure of its active ingredients and the formation of the product.

Since the 21st century, the plant extract industry has entered a golden period. This is on the one hand from the improvement of living standards and health awareness of people driven by the strong demand for plant extract products; on the other hand, benefited from the application of more advanced plant extraction technology (such as enzymatic extraction, ultrasonic extraction, supercritical extraction, microwave extraction, membrane separation technology, etc.), which greatly improved the production efficiency.

Plant extract industry development trend

Plant extracts downstream demand is strong, the industry is expected to maintain a growth rate of about 15% in the next 3-5 years. The future demand for plant extracts remains relatively strong for the following three reasons:

1. Accelerated global aging, old age, chronic diseases and other issues. With the strengthening of the concept of healthy consumption and the improvement of personal disposable income, the demand for space will rise faster.

2. Strong development of the food industry, in-depth research on natural products, “green food” and “health food” is becoming more popular.

3. With the rise of “value economy”, the trend of cosmetic industry is returning to natural, green, environmental protection and safety. China is the second largest cosmetic market in the world, and in terms of consumer generation, young consumers of the post-90s and post-95s prefer natural skincare products with plant-based ingredients.

Plant extraction methods and characteristics

Currently the methods commonly used to extract plant extracts include: ultrasonic extraction technology, microwave extraction technology, supercritical fluid extraction technology, large pore resin adsorption, membrane separation technology and so on.

1. Ultrasonic extraction: the use of ultrasonic cavitation to accelerate the leaching of useful plant components.

Advantages: short extraction time, simple extraction method, high extraction rate, low extraction temperature, to avoid high temperature and high pressure on the destruction of useful components.

Disadvantages: high requirements for containers, noisy operation, equipment is not easy to expand and other issues.

2. Microwave extraction: in the microwave field, due to differences in the absorption of microwave substances, some components can be selective heating, so as to extract.

Advantages: short extraction time, simple equipment design, less operating costs.

Disadvantages: equipment extraction mechanism is not clear, can not ensure the purity of the extracted material.

3. Supercritical extraction: supercritical fluid to replace conventional organic solvents for extraction and separate. Commonly used in volatile components, fat-soluble substances, highly heat-sensitive substances and valuable medicinal herbs.

Advantages: low extraction temperature, effective retention of valuable components, no solvent residue, high purity of extraction, simple operation.

Disadvantages: high-pressure equipment, purchase and operation of the input cost is large, equipment operation cost is high.

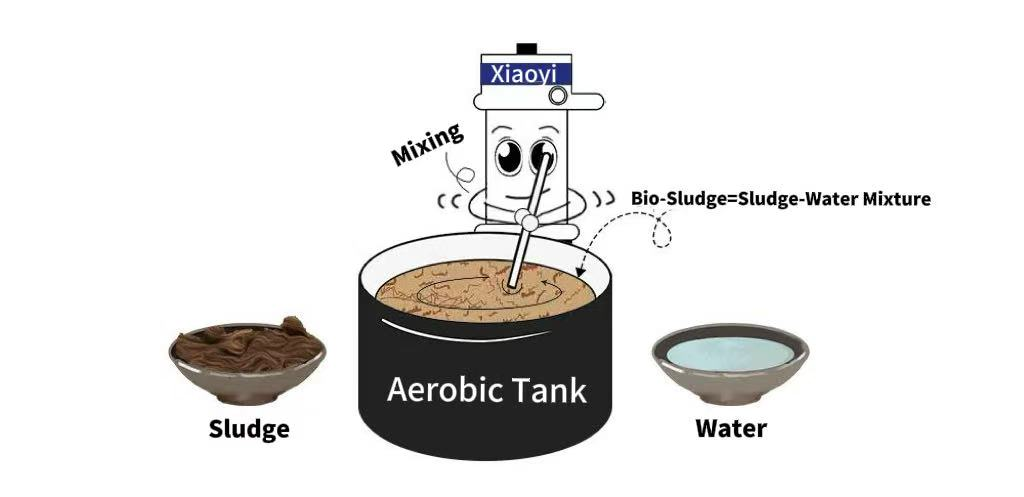

4. Membrane Separation Technology: It is a separation technology based on semi-permeable membrane, which realizes the separation and concentration of different substances through pressure drive.

Characteristics: no phase change, energy saving, small size, detachable, operating temperature close to room temperature, purely physical extraction process, simple process, which can realize precise separation and efficient concentration of target components.

Process advantages of membrane separation technology in phytoextraction

High-efficiency separation: It can realize high-efficiency separation and concentration of target components, reduce the interference of impurities, and improve the purity and stability of products.

Energy saving and environmental protection: pressure-driven, low energy consumption, while avoiding high temperature, chemical treatment and other factors that cause pollution to the environment.

Easy to operate: simple process, easy to automate control, reducing manual operation and human error.

Strong adaptability: It is suitable for different types of plant extract liquids.

With the expanding market of plant extracts and increasing consumer demand for high quality products, the application of membrane separation technology in plant extract liquid concentration will be more widely used. This not only helps to improve product quality and purity to meet market demand, but also provides strong support for technological innovation and sustainable development of the plant extract industry.

Case Application

1. Plant extract concentration system

Project scale: 800m³/d

Process flow: pretreatment + secondary NF

2. Plant extract concentration system

Project scale: 1000m³/d

Process flow: pretreatment + RO