Textile Printing and Dyeing Wastewater Treatment and Reuse

Due to variations in fiber raw materials, dyes and dyeing and finishing processes, the composition and concentration of printing and dyeing wastewater differ significantly. Generally, however, this type of wastewater is characterized by high color intensity, poor biodegradability, high COD, large fluctuations in water quality and strong alkalinity, making it challenging to treat.

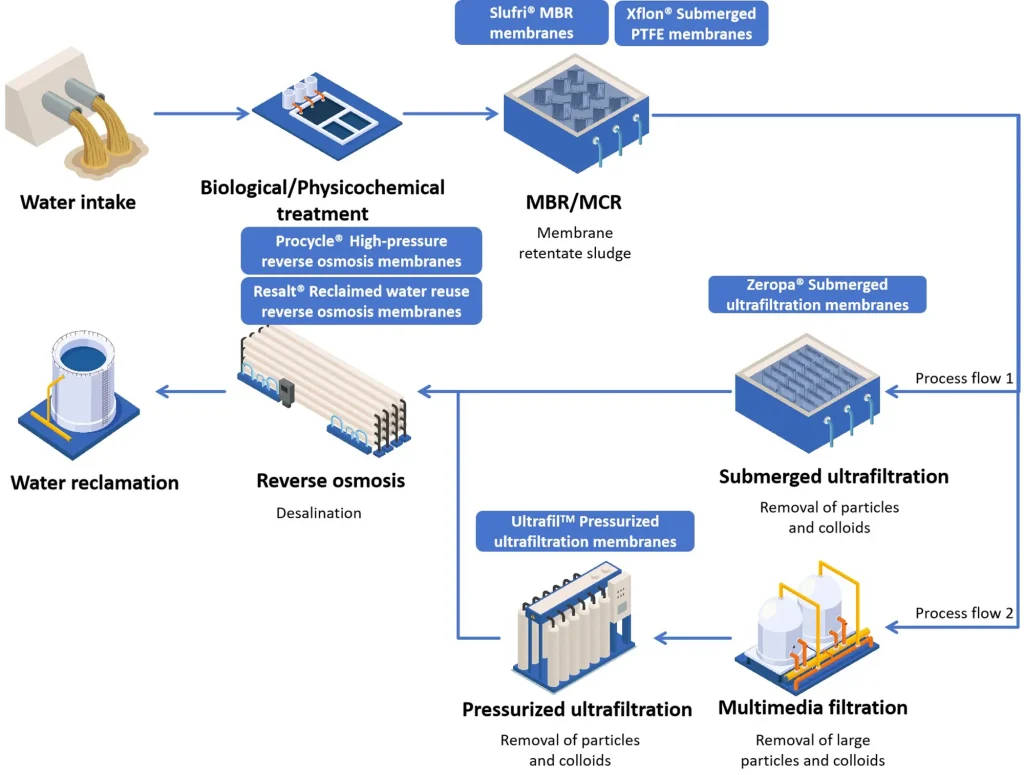

In recent years, increasingly stringent environmental standards have raised requirements for effluent quality and reuse rates of printing and dyeing wastewater, with some regions even advocating for “zero liquid discharge” policies. To address this, Shuiyi has developed specialized membrane products such as MBR membranes, submerged ultrafiltration (SMF) membranes, ultrafiltration (UF) membranes and reverse osmosis (RO) membranes. These help users increase the recovery rate of printing and dyeing wastewater and ensure compliance with discharge standards. Shuiyi has established numerous successful cases both domestically and internationally.

Project name: Textile Wastewater

Treatment capacity: 14400 T/D

Supplied products: UF + RO

Commissioning year: 2014