MBR Membrane

The “Super Sieve + Microbial Manager” of Wastewater Treatment

Hey, friends interested in environmental protection and technology!

It’s Xiaoyi from Shuiyi Membrane Technology back with another lesson!

Foreword

Today, let’s talk about electroplating wastewater — a major “headache” for many electroplating plant owners. Heavy metals, cyanides, complex compounds…It’s like a party for “toxic substances”!

Don’t panic! The MBR (Membrane Bioreactor) is here, shining brightly as the “Water Treatment Expert”, specialized in tackling all challenges!

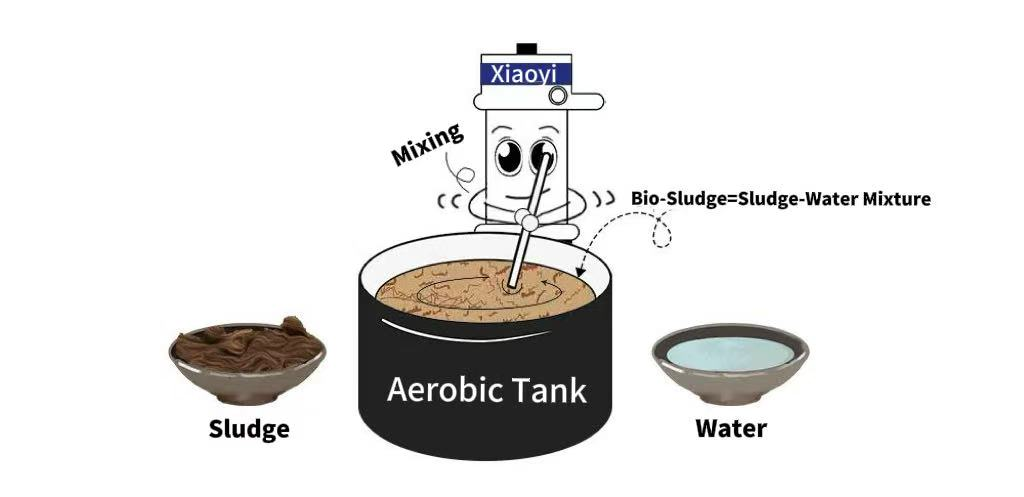

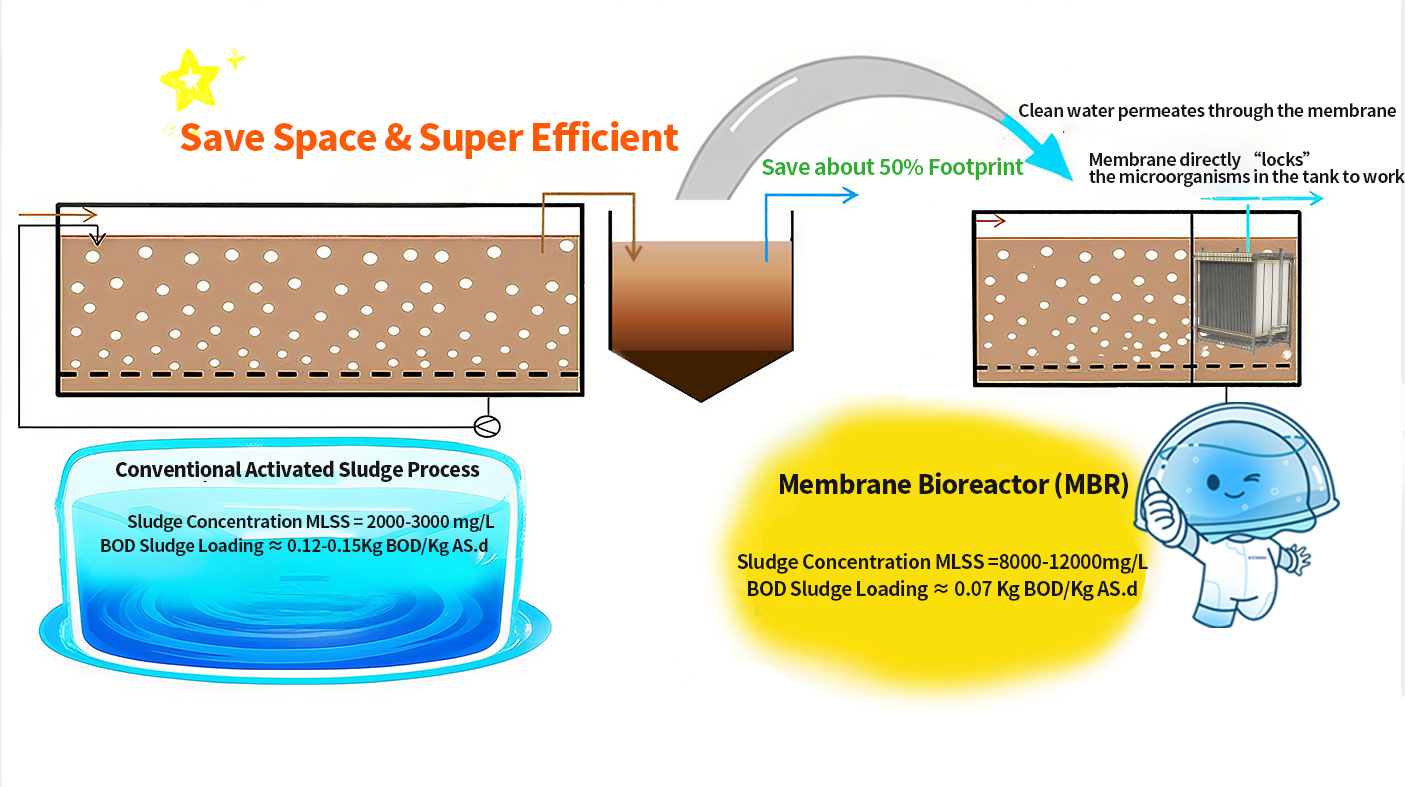

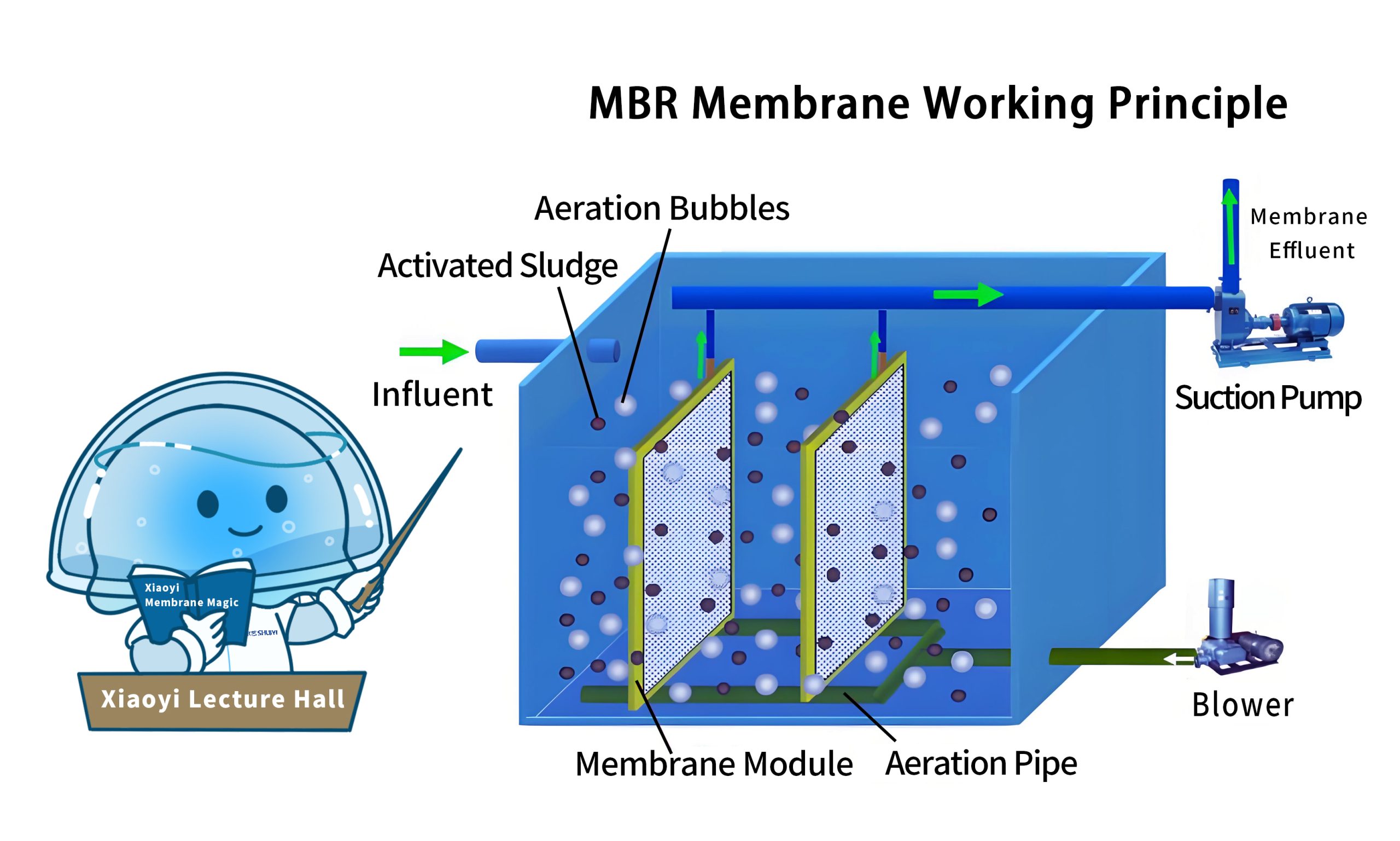

Image MBR as installing a high-precision sieve (membrane module) in the biochemical tank, while also hiring a team of super powered “microbial cleaners”. In conventional methods, the microorganisms (activated sludge) and water have to “break up” (settle and separate), which is slow and space-consuming. With MBR, the membrane directly “locks” the microorganisms in the tank to work, and clean water “permeates” through the membrane! It saves space and is highly efficient!

MBR Membrane Conquers Electroplating Wastewater with Three Unique Skills!

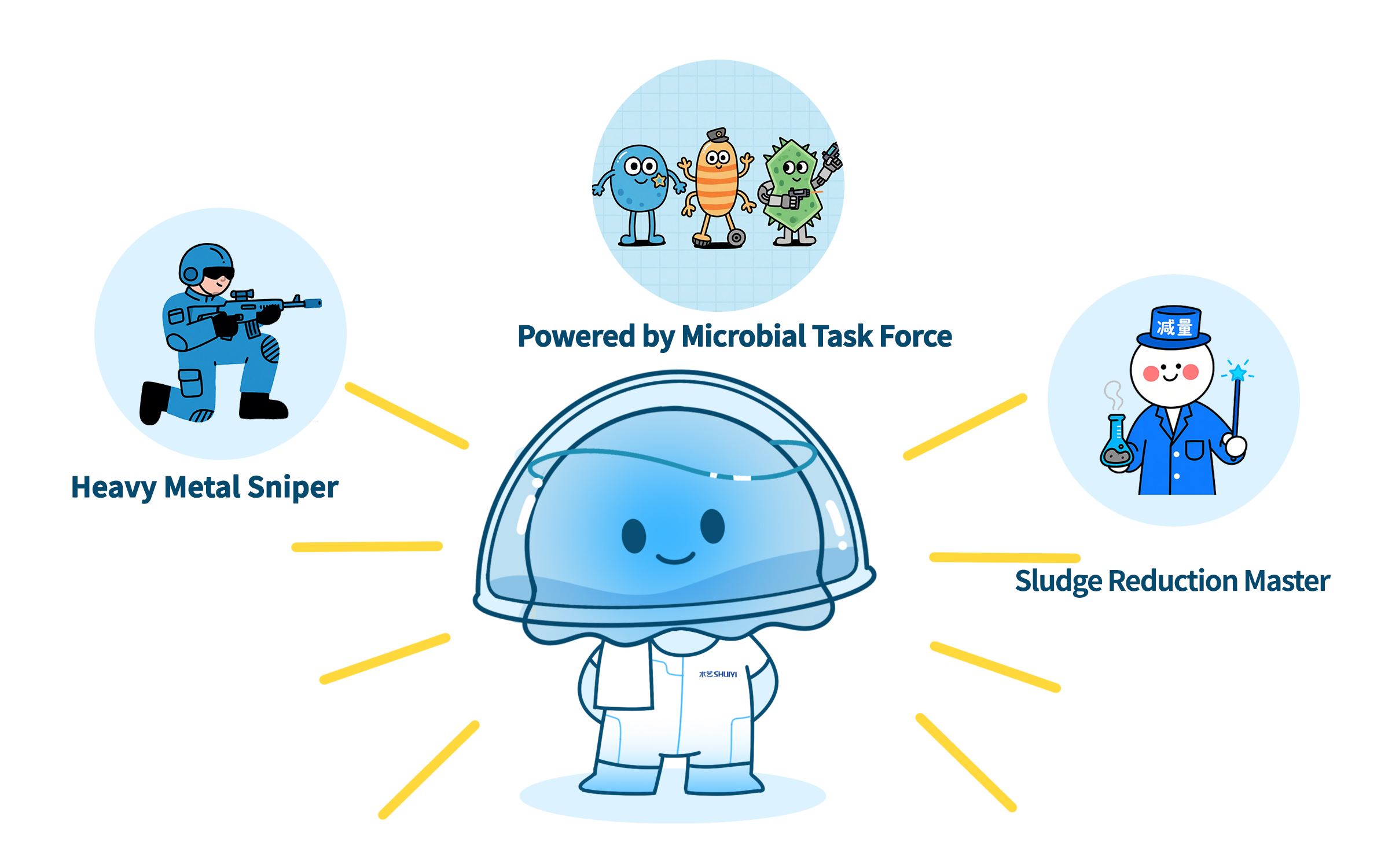

- “Heavy Metal Sniper” Heavy metals in electroplating wastewater are like nail households. Specialized microorganisms, a “special task force”acclimated within the MBR system, can effectively break down some organic complex compounds, releasing and transforming heavy metal ions. More importantly, those ultrafine membrane pores (0.05 microns)block sludge containing heavy metals, colloids and undecomposed large molecules! The effluent is clear with significantly reduced heavy metal and suspended solid content, easing the burden on subsequent advanced treatment.

- Boosted by the “Microbial Task Force” MBR can maintain an ultra-high concentration of activated sludgein the tank, meaning more “gluttonous” microorganisms to deal with hard-to-degrade organic matter (like some surfactants or additives). COD and ammonia nitrogen removal rates are excellent; water quality is stable and it’s not afraid of fluctuations in water volume or quality causing “trouble”.

- “Sludge Reduction Master” Microorganisms work more efficiently in the “rat race” of the MBR tank, producing significantly less excess sludge compared to conventional methods, saving a lot on sludge handling costs and headaches!

Shuiyi Membrane Tips:

- Choosing the right membrane is essential! Electroplating wastewater has a “bad temper” (complex composition, potentially strong acids, alkalis and oxidizers). Shuiyi Membrane’s anti-fouling, chemically resistant PVDF and PTFE-based membranes are the preferred choice, offering long life and low maintenance.

- Pretreatment is the “Membrane Guardian”! Proper pretreatment like pH adjustment, oil removal and cyanide destruction is essential for MBR membranes to “live a long life” and perform optimally.

In summary: MBR membrane technology, with its advantages of highly efficient solid-liquid separation, high sludge concentration, superior effluent quality and small footprint, has become a “green weapon” for solving the challenges of electroplating wastewater treatment. It turns difficult-to-treat wastewater clear, helping the electroplating industry move towards cleaner production!

Want to learn more about how our “membrane magic” can solve your wastewater challenges? Feel free to contact Ningbo Shuiyi Membrane anytime! We are dedicated to purifying every drop of water with membranes!

END