Shuiyi Slufri® SMU-E Series Equivalent to Mitsubishi 50E0025SA

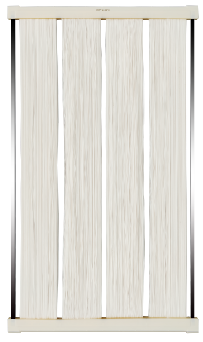

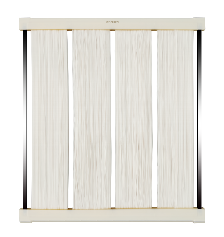

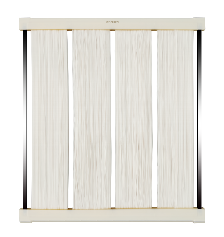

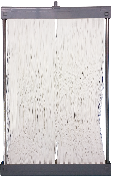

The SHUIYI SLUFRI® series reinforced PVDF hollow-fiber membrane modules are designed for direct replacement of 50E0006SM, 50E0015SA, 50E0025SA, and 56E0040SA.No system retrofit is required, and installation is simple and efficient.

Shuiyi Slufri® Series MBR Membrane Products utilize low-pressure high-flux PVDF hollow fiber composite membranes with evenly spaced fiber technology. The membrane cassette is equipped with apulse aeration device, featuring high operational flux, stable water quality, strong anti-fouling capability, long service life, and low energy consumption. Additionally, compared to traditional MBR membranes, the air-to-water ratio can be as low as 5:1, reducing energy consumption by more than 40%, making it widely applicable in municipal and industrial wastewater treatment sectors.

Description

- Small pore size, large flux

The membrane fibers have an average pore size of 0.05μm, with uniform pore distribution, high porosity, higher anti-fouling properties, and longer service life. By adjusting the membrane material formula and upgrading the process, the operational flux has increased by 25%. - Long service life

The membrane fibers have a tensile strength >150N and peel strength >3N, can withstand higher intensity backwashing without breaking or peeling, and have a long service life. - Anti-fouling, not trap mud

The series uses automated spacing of hot melt adhesive, ensuring evenly spaced and neatly arranged membrane fibers, effectively enhancing the anti-fouling properties of the membrane elements, preventing mud trapping, reducing cleaning frequency, and increasing water production efficiency. - Low operational energy consumption

Shuiyi ESP high-efficiency energy-saving membrane assemblies use large bubble pulse aeration technology, reducing aeration by 40% compared to traditional continuous aeration, lowering the air-to-water ratio to below 5:1, and significantly reducing energy consumption. - Operable without backwashing

With the new product upgrade, it can operate without backwashing, effectively improving water production efficiency and quantity, achieving energy savings and consumption reduction.

Data Sheet

| Parameter | Unit | ||||

| SMU-7.5D | SMU-15E | SMU-30EP | SMR-40E | ||

| Performance Parameters | Effective Membrane Area | 7.5 | 15 | 30 | 40 |

| Fiber Outer Diameter | 2.6 | 2.6 | 2.6 | 1.65 | |

| Pure Water Flux | ≥ 100 (TMP 20 kPa, 25℃) | ||||

| Operating Weight | 10 | 20 | 30 | 36 | |

| Operating Parameters | Recommended Membrane TMP | 0-35 | |||

| Maximum Backwash Pressure | 70 | ||||

| Backwash Flow Rate | 30-50 | 30-70 | |||

| Operating Flux | 10-30,25℃ | 30-45,25℃ | |||

| Operating Temperature | 5-45 | ||||

| Operating pH Range | 2-10 | ||||

| Air Scouring Intensity (Pulse) | 50-70 | ||||

| Air Scouring Intensity (Continuous) | 80-120 | ||||

| Chemical Cleaning pH Range | 1-12 | 1-11 | |||

| Maximum NaCl Tolerance | 3000 | ||||

| Permeate Turbidity | ≤ 0.8 | ≤ 0.5 | |||

| Permeate TSS | ≤ 5 | ≤ 5 | |||

Notes: 1.Operating and backwash flow rates depend on overall system design and maintenance conditions.

2.Air scouring intensity is calculated based on the projected membrane surface area (upper exposed section) under standard conditions.

3.Chemical cleaning parameters are based on tests at 30°C standard conditions.

4.Permeate water quality may vary slightly depending on raw water characteristics.