PTFE is highly resistant to acids, alkalis, high temperatures and solvents. Thanks to these outstanding properties, PTFE has been widely applied across various industries. In the field of water treatment, there is also a hollow fiber membrane product manufactured using PTFE as the raw material.

As one of the earliest companies in China to research PTFE hollow fiber membranes and achieve industrialization, Shuiyi has possessed multiple core patents and technologies, with extensive experience in the production and application of PTFE hollow fiber membranes.

Core Technology 1: 100% PTFE Material — Suitable for Various Complex Environments

Unlike conventional membrane materials such as PVDF, PSU and PES, PTFE is insoluble in organic solvents and therefore cannot be manufactured through conventional phase inversion processes. In addition, due to its excellent physical and chemical properties, PTFE has an extremely high melt viscosity, making it unsuitable for preparation via melt stretching processes. Currently, PTFE membrane products are primarily produced through an extrusion-stretching-heat setting process, where the selection of raw materials and subtle variations in the process can lead to significant changes in membrane performance.

Due to the difficulties in processing PTFE materials, high production costs, and significant technical challenges, some manufacturers choose to produce membrane products by combining PTFE with other materials. However, this inevitably compromises the membrane’s resistance to chemicals such as acids, alkalis and solvents.

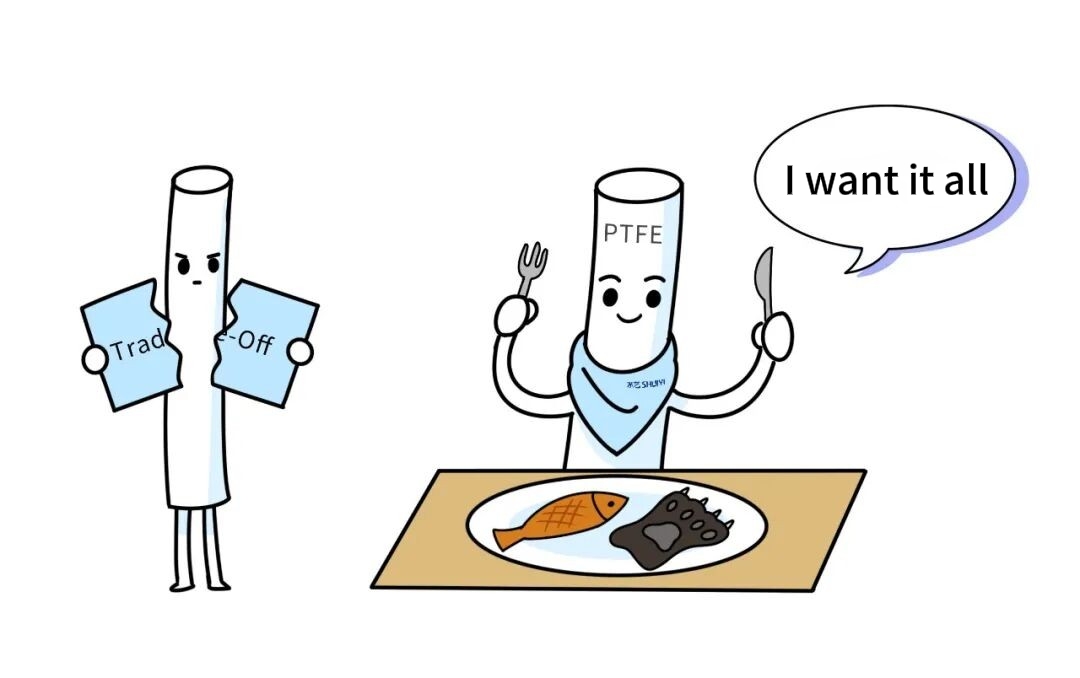

Core Technology 2: Wrapped Composite Structure — Breaking the “Trade-Off” Effect

In the membrane separation field, there exists a “Trade-Off” effect: membranes with high flux often exhibit low separation accuracy, while membranes with high separation accuracy tend to have poor permeability.

- To overcome the limitations of the “trade-off” effect, Shuiyi’s PTFE hollow fiber membrane adopts an innovative composite structure. First, a hollow fiber membrane with large pore size and high porosity (75% – 80%) is fabricated as the support layer. Second, an ultra-thin (10 μm) PTFE flat sheet membrane using a biaxial stretching-heat-setting process is produced as the separation layer. Finally, the support layer and separation layer are sintered together through a high-temperature composite sintering process.

Core Technology 3: Permanent Super-Hydrophilic Technology

Shuiyi’s PTFE hollow fiber membrane employs a proprietary super-hydrophilic modification technology, eliminating the transmembrane resistance caused by the hydrophobicity of PTFE materials. As a result, the membrane fibers exhibit excellent hydrophilicity and can be fully wetted within 3 seconds.

Typically, conventional hollow fiber membranes cannot be excessively dried and require protection with glycerol. However, this method can lead to problems such as mold growth, reduced membrane flux and the generation of organic wastewater during operation.

After hydrophilic modification, Shuiyi’s PTFE hollow fiber membrane can be stored, transported and installed in a dry state. This perfectly resolves the problems associated with conventional glycerol protection, eliminates secondary pollution and required no surface wetting agents. The membrane can be used directly after immersion in water. In addition, the hydrophilic performance is stable and reliable, and neither continuous operation nor frequent backwashing will affect its hydrophilic performance.