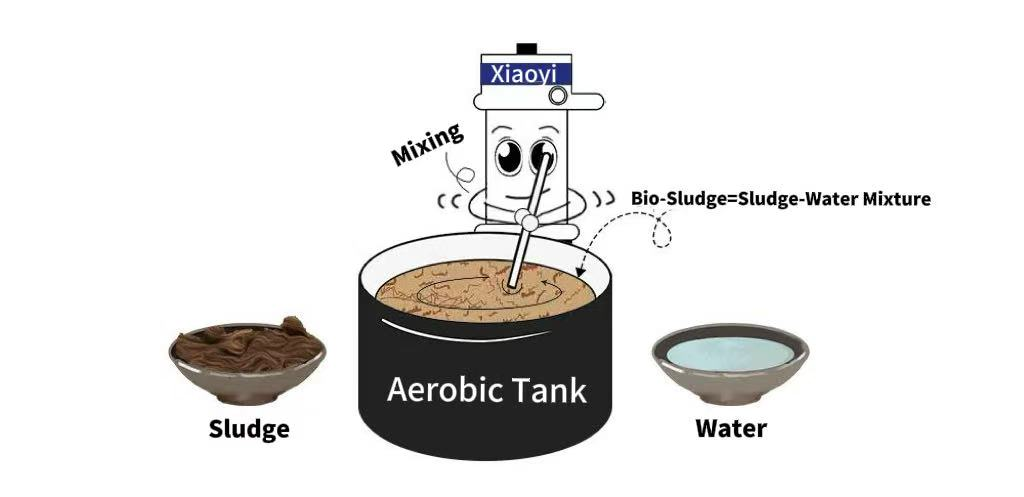

Bio-Sludge refers to the mixture of activated sludge and wastewater in anaerobic, anoxic and aerobic tanks. In the context of MBR, it primarily denotes the sludge-water mixture in the aerobic tank.

It is well known that a key factor limiting the development of membrane-based water treatment is membrane fouling. In addition to the inherent performance of the membrane itself, the operating environment of the membrane — i.e., the bio-sludge — is also a critical factor affecting the rate of membrane fouling.

To facilitate understanding, we attribute the relationship between bio-sludge and the membrane to the concept of “filterability”. Bio-sludge with strong filterability requires minimal energy to achieve solid-liquid separation; conversely, poor filterability increases energy consumption and is more likely to cause irreversible membrane fouling.

So, how can we evaluate the filterability of incoming bio-sludge?

Under typical field conditions with limited resources, we can measure SV30 and use sedimentation performance as a simple proxy for filterability. It the supernatant is clear and the sludge-water interface is distinct, it indicates good settling performance. In a laboratory settling, we can vacuum-filter well-mixed bio-sludge through filter paper under a pressure of -50Kpa and record the time required to filter 100mL of filtrate. During filtration, a small stirrer should be used to maintain continuous mixing. Generally, a filtration time of less than 300 seconds indicates good filterability.

What factors influence the filterability of bio-sludge?

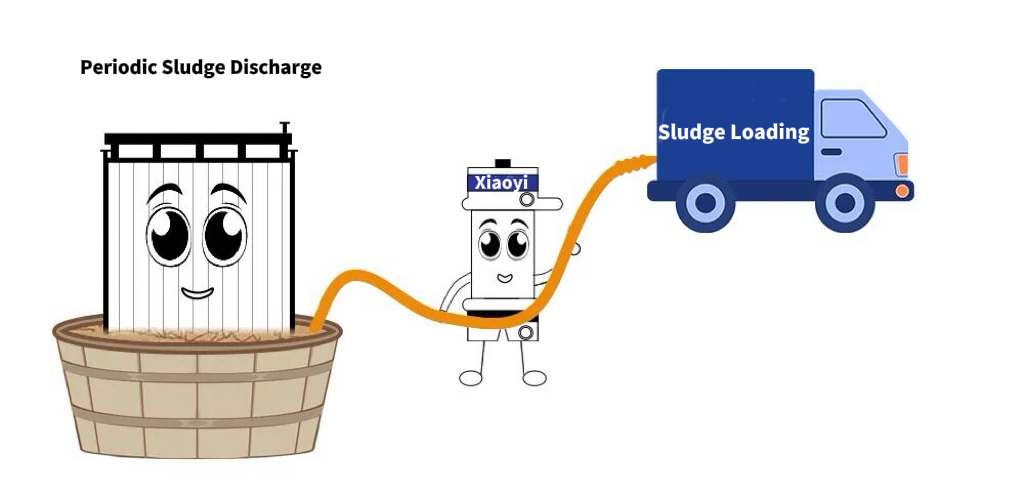

Sludge Concentration

This is straightforward: the higher the sludge concentration in the bio-sludge, the greater the amount of sludge retained per unit volume of water filtered by the membrane. Under constant aeration intensity, more sludge absorbs onto the membrane surface per unit time, accelerating membrane fouling. Therefore, to improve filterability, the system requires regular sludge discharging. In MBR processes, the sludge concentration is typically maintained between 8,000 and 10,000 mg/L.

Sludge Properties

Sludge properties are mainly related to its physiological state, influenced by factors such as sludge age, sludge loading, particle size and microbial activity. For example, young sludge often exhibits high activity and can treat more wastewater, but it also tends to have small, dispersed particles, resulting in poorer filterability compared to middle-aged or older sludge. When sludge quantity is too low, incoming COD may not be thoroughly treated, leading to the formation of intermediate products that also reduce filterability. We can roughly assess filterability based on sludge color, floc size, clarity of the supernatant and settling ratio.

Organic Components in Water

Organic Components primarily include pollutant inherent in the wastewater, especially large-molecule hydrophobic organics such as petroleum hydrocarbons. These are particularly hazardous to MBR systems. For PVDF-based MBR membranes, mineral oils concentrations should be controlled below 3 mg/L. Additionally, extracellular polymeric substances (EPS) and microbial metabolites released by activated sludge — organic compounds releasing during metabolism or cell-death — readily encapsulate microorganisms, forming zoogloeal. During filtration, these substances adhere to the membrane surface as a gel, causing rapid flux decline.

Temperature

Temperature is another important factor affecting filterability. In summer, higher water temperatures reduce water viscosity, improving filterability. The opposite occurs in winter.